Why do you need ERPNext?

- General

Why do you need ERPNext?

Overview

ERPNext is an open-source web-based system aimed at small and medium-sized businesses. It assists companies with accounting, human resource management, sales, purchase, inventory, CRM, administration, project and task management, manufacturing, and even website. ERPNext is built using Python, Frappe, and MySQL.

ERPNext is a full-featured business management solution that helps SMEs (Small and mid-size enterprises) to record all their business transactions in a single system. With ERPNext, SMEs can make informed, fact-based, timely decisions to remain ahead of the competition. It serves as the backbone of a business adding strength, transparency, and control to your growing enterprise.

Why ERPNext?

Today, small and medium-sized businesses (SMEs) also face some of the problems that large enterprises do. One of them is planning and managing their resources. SMEs face similar complexities but have limited resources to deal with them.

Small businesses (like their bigger counterparts) have to:

- Do accounts to track their sales/purchases.

- Do their taxes.

- Pay their employees.

- Manage deliveries within promised timelines.

- Deliver quality goods and services.

- Communicate with customers, and answer their queries.

Large enterprises invest millions of dollars in highly sophisticated systems like SAP. SAP and similar systems can handle requirements from these large enterprises to bring their multi-country, multi-company, multi-currency, global businesses into a single platform. This has helped them achieve consolidation of data/records in the fundamental processes such as accounting, taxation, payroll, reporting, and supply chain to name a few.

In contrast to large enterprises, SMEs have been left out of the 1st wave of the digital revolution (1995-2015). The main reason for being left out is that they don’t have the financial resources to license, hire programmers and customize such software to match their needs. Systems like SAP have been a no-go for most SMEs. Such systems need a minimum CAPEX or OPEX layout of $100k (Yes, One Hundred Thousand Dollars) and upwards. Even with cloud offerings (Software as a Service, SAAS) from such vendors, there is no easy Do It Yourself (DIY) people can feel confident about.

So even today, small businesses continue to struggle to keep things organized. They often use a mix of applications and tools such as spreadsheets, accounting software, and web-based CRMs to manage their day-to-day record keeping. As a consequence, they have to access different systems to understand customers’ master data, sales, cash flows, or profitability. The information exists in different silos. It becomes hard to combine the data to get useful insights or alerts. This leads to SMEs being reactive instead of proactive in their day-to-day operations. With such a constrained way of working, there’s limited scope for growth.

ERPNext addresses some fundamental problems SMEs struggle with when managing their resources:

- Affordability: It is Free and Open Source Software, freely available to download and install.

- Completeness: All necessary modules are available.

- Customization: It is easy to add fields, or add more features.

- Efficiency: Computing requirements are relatively low (cheaper to host and manage).

- Wholesomeness: A single system and database that allows multiple users to record transactions or extract data simultaneously.

ERPNext helps in

- Track all invoices and payments.

- Know what quantity of which product is available in stock.

- Identify and track your key performance indicators (KPIs).

- Identify open customer queries.

- Manage employee payroll.

- Assign tasks and follow up on them.

- Maintain a database of all your customers, suppliers, and contacts.

- Prepare quotations.

- Track your budgets and spending.

- Determine effective selling price based on the actual raw material, machinery, and effort cost.

- Get reminders on maintenance schedules.

- Publish your website.

And many more.

ERPNext Modules

- Accounting

- Asset management

- Customer relationship management (CRM)

- Human resource management (HRM)

- Payroll

- Project management

- Purchasing

- Sales management

- Warehouse management system

- Website

- Manufacturing – Manufacturing

- Point of sale (POS) – Retail

- Student Information system – Education

- Hospital Information system – Healthcare

- Agriculture Management – Agriculture

- Nonprofit Organization – Non Profit

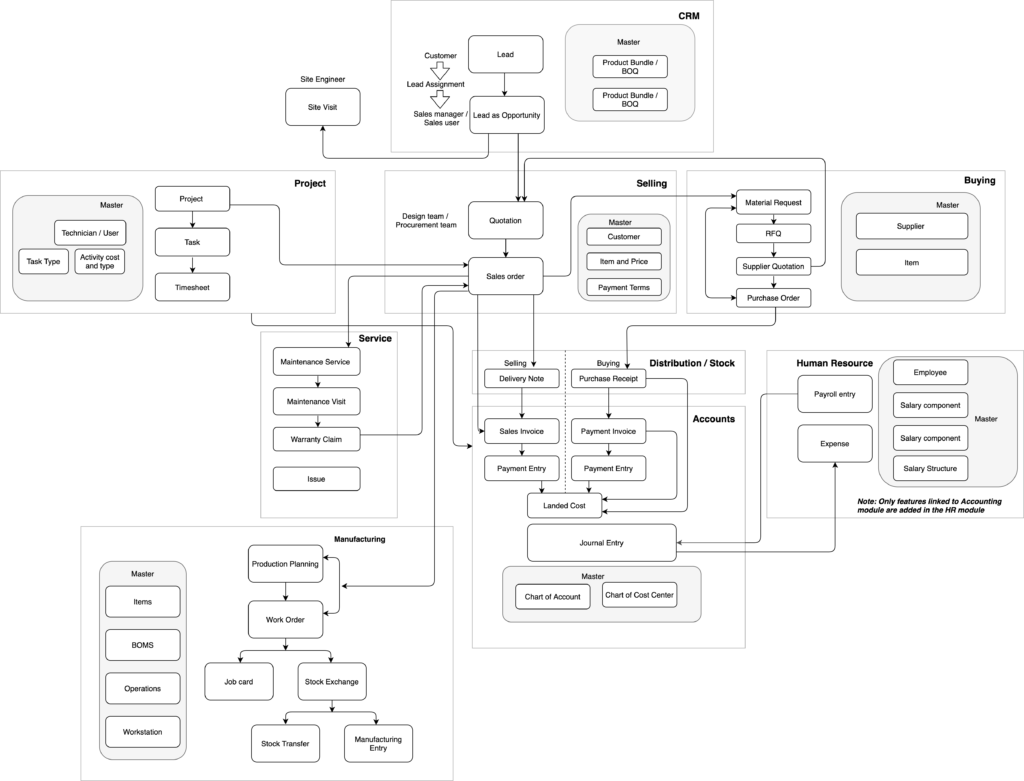

Flow Chart for all the modules

This diagram covers how ERPNext tracks your company information across key functions.

HR Module

The Human Resources (HR) module covers the processes related to the HR department of a company. It maintains a complete employee database including contact information, salary details, attendance, performance evaluation, leaves, and appraisal records.

The most important feature here is processing the payroll by using Payroll Entry to generate Salary Slips. Most countries have complex tax rules stating which expenses the company can make on behalf of its Employees.

-

Workflow of HR module

- All employee data is added to the system. This includes their details, type of employment, department, designation, branch, etc. All employees who interact directly with the ERP are also given user accounts.

- A recruitment pipeline is set up. This begins with creating a staffing plan for the financial year. As vacancies open up, a job opening entry is made. Then, the process of hiring takes place through job applicant entries, finally ending with an appointment letter to the selected candidates.

- Leaves and holidays are entered into the system based on the company’s leave policy. A leave ledger is used to keep track of employee leaves.

- The employee’s lifecycle is tracked from beginning to end. Starting from employee onboarding to appraisals, KRAs, promotions, transfers, all the way to employee separation.

- Payroll management is set up. Once the payroll period, income tax slabs, and salary structures are entered, it allows Ava’s team to generate salary slips for employees. Payroll entries are used for bulk processing of salary slips.

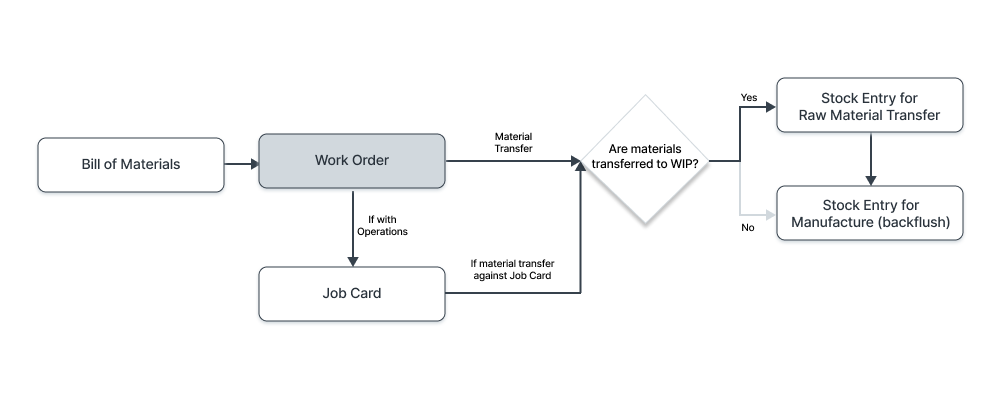

Manufacturing Module

The Manufacturing module in ERPNext covers all necessary features a Manufacturing business would need. There are options to take a Work Order, enter stock of items, create a Production Plan, create a Downtime Entry, manage the Bill of Materials for Finished Goods / Template Items, generate reports, and more.

Different types of manufacturing like make to stock, make to order, and engineer to order can be managed in the ERPNext Manufacturing module.

-

Workflow of the Manufacturing module

- All the individual items are added to the ERP. This includes every single material, component, and service that Spindle uses for manufacturing, along with the final products. (e.g., Yarn, thread, dyes are considered separate Items, but so are shirts, jackets, and pants.)

- Workstations for various operations are created. Details of operating costs, production capacity, working hours, etc. are all entered and saved.

- Manufacturing processes are saved as Operations. Each Operation processes and furthers raw materials in the manufacturing path. Operations are conducted at Workstations. (e.g., Dyeing fabric and cutting the fabric are considered Operations that take place at separate Workstations.)

- A Bill of Materials is created for each product that Spindle makes. This includes sub-assemblies and final products. Each BOM is made using previously-entered raw material Items to create a final product Item. Details of the quantity of raw material used, unit of measurement, operations, etc. are all entered.

- Work Orders are created as a signal for the production of a certain Item. Every Work Order uses BOMs (or multi-level BOMs), Operations, and Workstations to determine what is to be made, how it will be made, and where it can be made.

- For every Work Order that is made, a Job Card is issued. This is used by the operators of a Workstation to issue Material Requests and Stock Transfers to begin producing Items.

- The production department can create Production Plans against Material Requests. This allows them to keep up with the procurement of materials, based on the number of finished products that need to be manufactured.

Related content

Auriga: Leveling Up for Enterprise Growth!

Auriga’s journey began in 2010 crafting products for India’s