Colence Leather

Crafting Operational Excellence Through a Tailored ERP Solution

- Integrated Business Solutions

Colence Leather, a leading leather manufacturer in Bahadurgarh, Haryana, specializes in premium PU and PVC leather for diverse industries, including footwear, furniture, car/motor/airline seat covers, and leather accessories. With a global presence and a customer-centric approach, they source materials from India and China, collaborating with reputable suppliers.

Seeking to maintain industry leadership, Colence Leather pursued a highly customizable ERP system to enhance operational efficiency and strengthen their global presence, ensuring seamless integration and exceeding customer expectations.

Problem Statements

With their existing ERP system, they were facing issues such as customisation and scalability. Therefore, they partnered with Auriga IT to develop a tailored and scalable solution that can be easily implemented on popular or pre-existing ERP systems, solving operational challenges such as:

- Integration Challenges- Colence Leather struggled to find an ERP solution compatible with their unique manufacturing processes.

- Specialized Requirements- They required a customizable, scalable ERP system that could seamlessly integrate with their day-to-day operations and meet their specific needs.

- Off-the-shelf Solution Limits- While utilizing existing market ERP solutions, they needed a customized solution that could meet distinct needs and help them overcome operational challenges.

Solutions

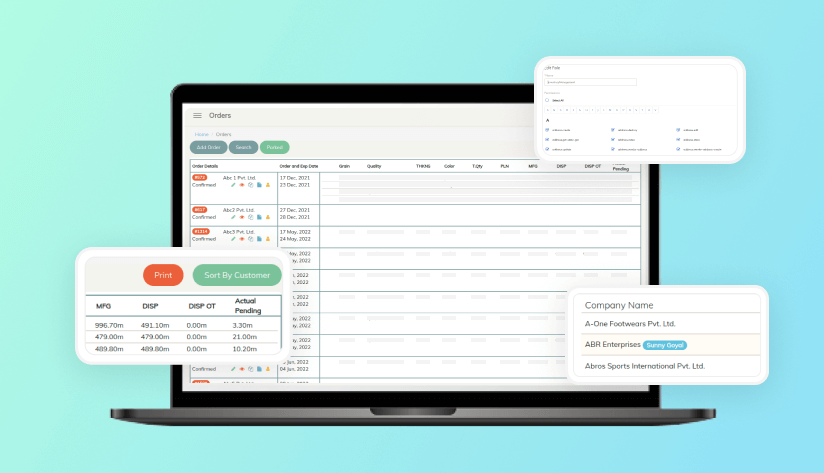

We comprehended the challenges faced by Colenece Leather and crafted a fully bespoke ERP solution from the ground up. We devised a series of modules, each tailored to address distinct requirements. Here are some of the key modules we developed:

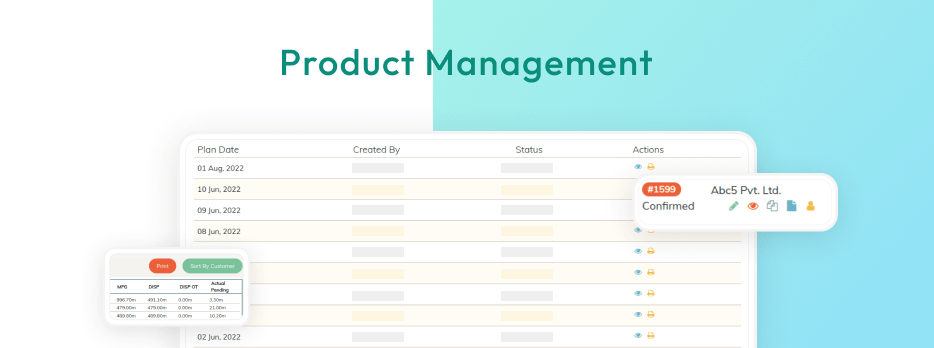

- Product Management- We added features such as product tracking, cataloging, and dynamic pricing, enabling efficient product life cycle monitoring, logical product categorization, and competitive pricing.

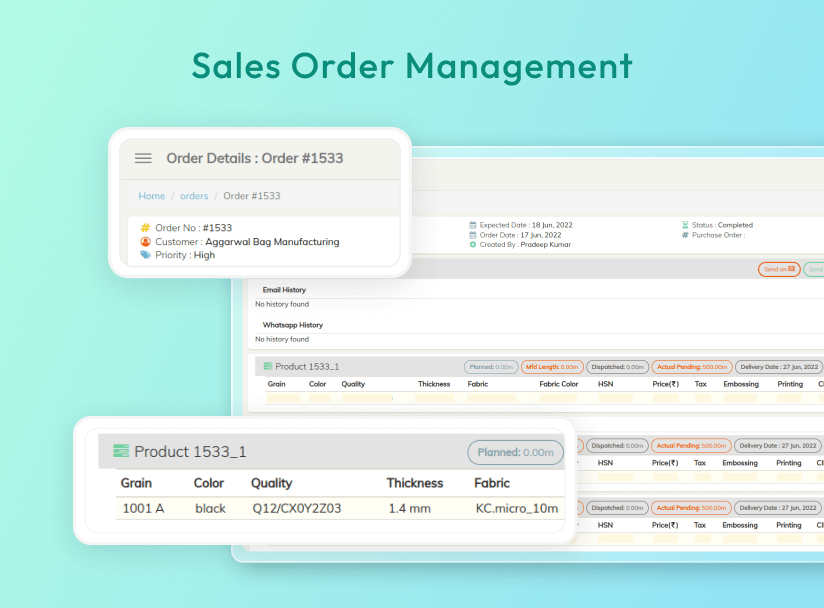

- Sales Order Management- This module simplified sales order management for Colence Leather, allowing easy tracking from creation to fulfillment, and enhancing processing for timely deliveries.

- Production Planning & QR Code Tracking- We developed a smart production planning module for optimal resource allocation and used QR codes for traceability and quality control in the leather production process.

- Inventory Management (Big Rolls, Small Rolls)- The Inventory Management module allowed efficient monitoring and management of varying-sized leather rolls, ensuring optimal stock, informed decisions, and smooth production. It provided real-time roll availability and a user-friendly interface for streamlined operations.

Project Outcome

- Transition to Paperless Operations- The entire factory/mill successfully made the shift to a paperless environment, significantly reducing administrative tasks and fostering sustainability.

- BI Empowerment- A unique Business Intelligence (BI) layer was developed that facilitated process optimization, reduction of production bottlenecks, and enhancement of overall efficiency.

- Enhanced Accuracy- The customized features and modules of the ERP system enabled Colence Leather to achieve superior accuracy in production, leading to improved product quality and heightened customer satisfaction.

- Smooth Integration- The bespoke ERP solution integrated seamlessly with their existing infrastructure, ensuring a smooth transition without any disruptions.

Related Case Studies

SLA Financials