GearX

Streamlining Repair Management Process with Low-Code Automation

- Digital Engieering

- ERP & CRM

About Client

GearX is a leading provider of tooling, Just-in-Time repairs, and 24/7 support for the automotive, manufacturing, and industrial rebuild/repair industries. They boast a team of lean manufacturing, assembly, and engineering experts.

Problem Statement

Despite their wealth of experience and expertise, the client faced bottlenecks in their repair management process. GearX relied on a manual workflow for managing repair requests, requiring manual updates and increasing the likelihood of inefficiencies, errors and delays. GearX needed a solution to Automate workflows, Enhance visibility and Improve accuracy.

The Solution

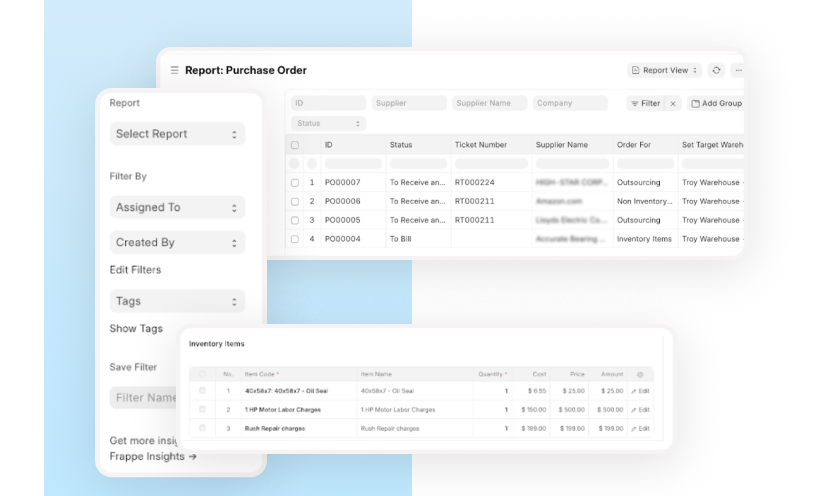

We proposed and implemented the solution focused on automating and streamlining the entire repair management workflow, ensuring seamless coordination between different stages and real-time status updates leveraging the Frappe low-code application development platform.

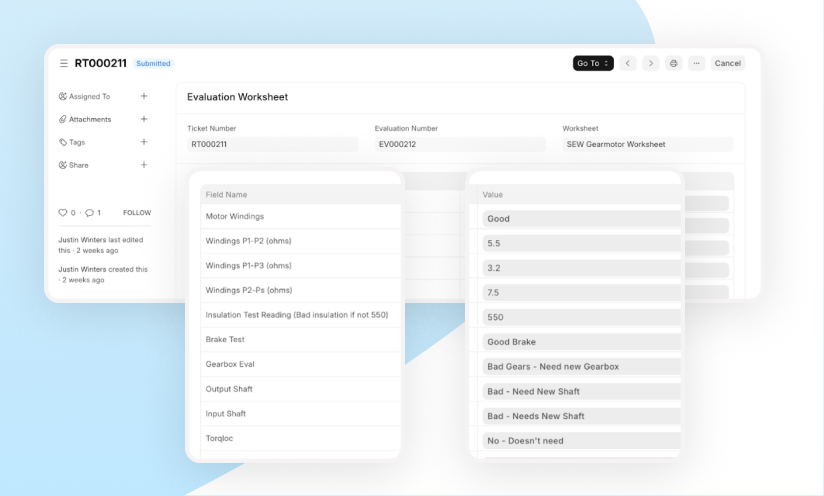

- Automated Workflow: Repair tickets now seamlessly progress through a defined workflow, triggering automatic status updates based on predefined events like evaluation, quote generation and approval, part availability, and work order status.

- Material Requirement Planning: The system automatically identifies and recommends required materials based on the item requirements listed in each repair ticket evaluation.

- Integrated Core Enterprise Resource Planning Systems: Essential functionalities for inventory management, purchase order management, invoicing, and accounting were integrated within the solution, providing a holistic view of operations.

- Project Profitability: The solution calculates profit based on the quote amount and actual costs like material, labour, and outsourcing services.

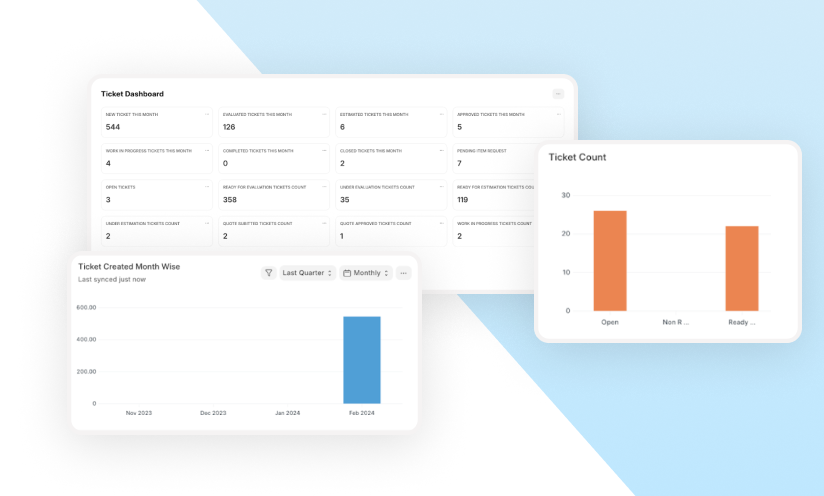

- Real-time Dashboard: Managers gain real-time visibility into repair statuses, project profitability, and resource utilization through a comprehensive dashboard.

Impact:

- Efficiently processed over 1,000 repair tickets per month.

- Successfully managed a vast inventory of 1,500+ items monthly.

- Facilitated over $50,000 in monthly sales through the platform.

Related Case Studies

SLA Financials