Basant Industries

Building a World-Class Digital Facility in Global Furniture Manufacturing

- Integrated Business Solutions

Client Overview

Founded in 1998 by Vinay Kumar, Basant Industries is a Jodhpur-based, global leader in furniture manufacturing, exporting 98% of its production. With state-of-the-art manufacturing facilities, Basant’s sprawling 935,000 sq. ft. factory houses dedicated testing labs, metal workshops, powder coating areas, and an expanded upholstery unit – all under one roof.

Problem Statement

Basant Industries wanted to improve visibility and embrace new technology to enhance production, cut costs, and identify constraints within the business.

- KPI Monitoring- Key performance indicators (KPIs), such as production output, on-time delivery rates, defect rates, and overall equipment effectiveness (OEE), are not tracked and monitored through a centralized system at Basant Industries. This makes it difficult for bottlenecks to be identified, improvement efforts to be measured, and data-driven decisions to be made.

- Real-Time Visibility of Production- Real-time visibility into production processes is lacking at the company. Up-to-date information on work-in-progress (WIP) status, machine utilization, or potential delays cannot be easily accessed by managers and supervisors.

- Data-Driven Decision Making- Manual data collection and spreadsheets are relied upon by Basant Industries for decision-making. This process is time-consuming, prone to errors, and lacks the depth of analysis needed to optimize production processes and identify cost-saving opportunities.

- Digital Data Capturing- Data collection methods at the company are largely manual and paper-based. Data inconsistencies, delays in reporting, and difficulty in consolidating information from different sources are caused by this. The company’s ability to gain accurate insights into its operations is hindered as a result.

- Production Planning- Production planning at Basant Industries is often based on intuition and historical data, rather than on real-time demand and capacity constraints. Overproduction of certain items, underproduction of others, and difficulty in meeting customer delivery deadlines can be caused by this.

- Line Balancing- Challenges are faced in balancing workloads across different production lines and workstations at the company. Some lines are overloaded while others are underutilized as a result, leading to production bottlenecks and inefficient use of resources.

- Lead Time Monitoring– Lead times for different products are not accurately tracked and monitored at Basant Industries. This makes it difficult to provide customers with accurate delivery estimates and can lead to customer dissatisfaction if orders are delayed.

- Quality & Compliance- A standardized system to track quality issues and ensure compliance with industry regulations is lacking at the company. Product defects, customer complaints, and potential legal issues can be caused by this.

Solutions

Digitizing Operations- Digital systems replaced manual processes across all production lines, including quality control, maintenance, planning, and defect tracking, resulting in a paperless environment.

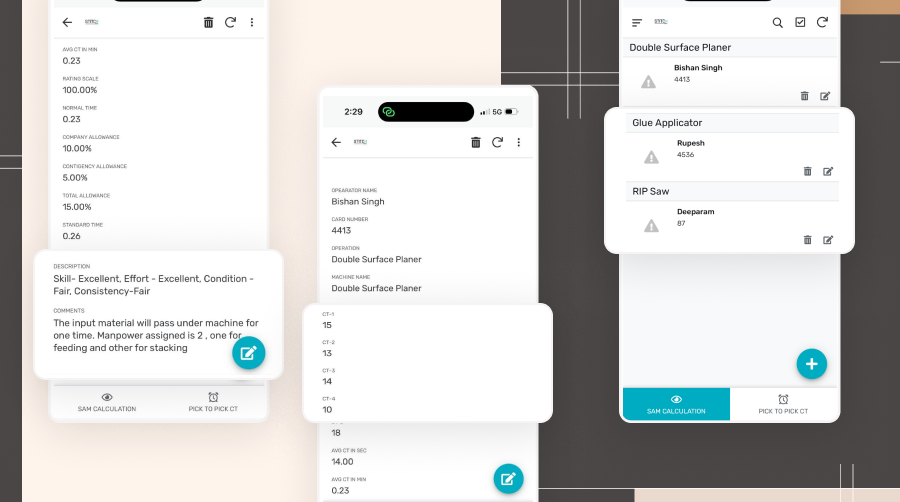

- Standardizing Processes– Industrial engineering studies were conducted to analyse (Standard allowed minute (SAM)) and optimize processes, identifying bottlenecks and enhancing productivity. This led to the establishment of uniform procedures, guidelines, and practices across Basant to ensure efficiency and sustainability.

- Sustenance- The long-term success of the Stitch system is ensured by a dedicated digital team, empowered by Auriga IT. Employee proficiency and seamless operation are ensured through comprehensive training. System maintenance, updates, and continuous improvement are guaranteed through standardized processes.

Project Outcomes

- Enhanced visibility & cutting optimization via defect bulletins and a marker function.

- Customizable inspections and AQL audits were conducted at all production stages.

- Digitization of manual processes improved efficiency and reduced errors.

- Standardized practices increased productivity and consistency.

- Stitch MES implementation enhanced operational effectiveness.

Related Case Studies

SLA Financials

Transformed the experience for SLA Financials customers

Digital Products & Software